Thanks to the collaboration with PFM, many leading Italian companies in the field of pastry products can now offer topping and filling creams packaged in a practical and innovative format: a piping bag ready for use.

This innovative packaging solution is produced by our Zenith VFFS machine powered by a volumetric pump for dense liquids suitable for dosing quantities from one gram to one kilo. The machine is designed to wrap any dense or creamy liquid product present in the confectionery sector such as liquid chocolate, custard, ricotta cream, etc.

For reference purposes, the production of one kilo of Ricotta cream cheese can reach 20 bpm. This type of packaged product can be sold fresh or frozen and stored for retail or wholesale.

This line features easily removable components to simplify cleaning operations and is constructed of materials that can endure aggressive washing cycles, which are commonly carried out in the dairy industry.

The bagger with the dosing pump is 3.2 meters high, 1.0 meters wide, and 1.8 meters deep. The line provides the highest standards of protection in environments with a significant risk of corrosion and ensures maximum convenience in sanitization.

The main advantage of producing a filled, ready-to-use bag from a reel of flexible film is that this production method avoids the laborious manual or mechanical filling of pre-formed piping bags.

Another advantage over traditional production methods is that the customer can decide the size of the bag and the amount of cream contained in it and can customize the printing on the film in real-time through the printer’s HMI panel.

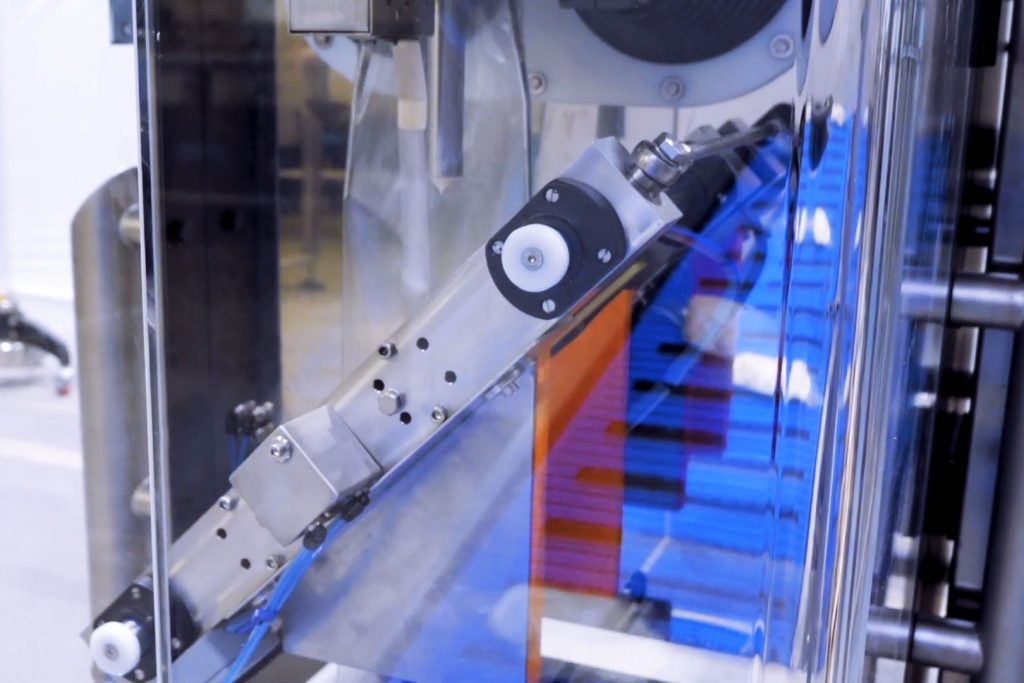

The Zenith bagger features an intermittent transverse sealing unit angled at 45 degrees, which produces a parallelogram-shaped pouch with one pair of opposite angles of 45 degrees and 135 degrees. This unique profile turns out to be more practical than the triangular or angle-sized trapezoidal profiles of traditional pre-formed pouches because it is suited to the squeezing operation, i.e., when a chef twists the closed end of the bag to push the cream out of the cut end.

Technological simplicity, combined with the relatively low cost of our packaging machine and the convenience of the final product have all contributed to the success of this innovative solution.